I had done this tutorial once before and someone asked me to make it available again on the website.

so here it is.

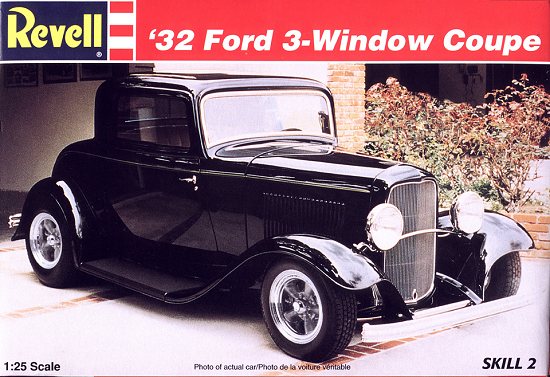

starting with a Revell 32 ford 3 window kit

great kit on its own but i am a sucker for chopping the top to give it a custom look

i know you can buy resin conversions, why would you bother when with a bit of time you can have the look you want, gain some experience and not spend anything extra to get there?

lets have a look at the body itself

i am going to concentrate on the top chop this time, later i will also remove the exterior hinges to give it a smoother look.

i lay out the lines for where i plan to cut, you can use 1/8 fine line tape to come up with a scale 3 inch top chop, i prefer to lay out my cut lines with a marker. the side cut lines i center on where the top hinge is on the door. once i chop it will be one less hinge to deal with.

in the rear i shift the cut line up to center with the rear window. if you dont do this then you end up with an odd shaped window when you are finished.

now some people dont bother with this next cut line. the reason i do this is so i can line up both the front and rear pillars without having to bend them out ruining the lines of the car.

the first cuts i am making are the vertical cuts near the rear window, if you wait until the end to do these it makes it a whole lot harder. i use the back of a hobby blade and repeatedly score the plastic along the line until i male it all the way through.

next, using a razor saw, i make the cuts to the highest lines on the sides.

i do the upper lines first because if you use the lower lines it will leave you with not much to hold on to when you have to make your other cuts. also the upper line of the side marks is in line with the lower line of the rear window cut. so cut straight through.

when you are through with your top cuts you will have 2 pieces that need a bit of cleanup.

now we will move to the lower section of the sides, starting at the rear window ( jog should be far enough from the window itself to make it easy to sand smooth later ) and start making the lower cuts so it looks like this.

then cut the small bits from the roof section

to make sure everything is all nice and level, i take a piece of sandpaper and lay it on a flat surface, then doing figure 8’s with the roof section until everything smooths out.

test fitting the rear section, if you have done your cutting carefully there should be very little filling to do later.

on the test fit we can see there will be a bit of file work needed to smooth out the side bodylines later.

this shows the reason we will be making the last roof cut, with the back section lined up properly, the front a pillars are slightly short of where they should be. the addition of the last roof cut will allow us to fix that.

using the razor saw i cut across the top

now to start attaching things back together. i have seen many people just glue top to bottom and think it was good enough. i prefer a bit of extra stability so i cut a few strips of .010 styrene to bridge across the joint and give more glueing surface.

i bend the styrene strip along the inside of the body and hold it in place with one of my handy dandy specialty clamps while i flow liquid cement along it and allow it to dry.

once glued in place, the strips give me a positive locating place to glue the rear section of the top on.

i glue the top on the same way i glued the strip on, once it dries it should look similar to this

now when i line up the front windshield section where it should be so it lines up, there is a very small gap at the sides of the top. we will fill this after we glue on the front.

check your fit from all angles so you make sure everything is straight before final glueing

once the front is glued in place ( using the same method as the rear with the shims from behind to give the joint strength ) i use some more of the .010 styrene to fill the joint between the front and rear roof sections. the less filler i have to use later, the better.

more shims to tighten up the joints around the rear window.

now trim off the excess plastic from the shims and sand smooth.

still needs a bit of filing to straighten out a bit of the door lines and upper bodyline, but so far so good.

looks straight from the front

rear fits tightly and wont require alot of filler

time for some putty to smooth out some of the rough spots

i sanded down with a sanding stick once the filler dried and then hit it with a coat of primer to help see anything else that needs to be tweaked.

it will require a little bit more filing and sanding but for the most part it is done and total bench time, not counting the waiting for glue to dry, was about an hour so far.

i have a few different ideas i am throwing around for this kit but they are going to have to wait until i get a few of my current projects off the bench.

cya a bit later